|

|

|

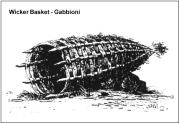

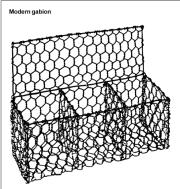

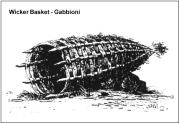

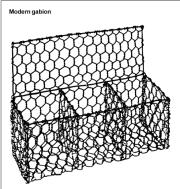

Beginning in the 16th century, engineers in Europe used wicker baskets - Italian gabbioni -filled with soil to fortify military emplacements and reinforce river banks. Today, the same simple technology - now known as “gabions” - is used as the building blocks of low-cost, long-lasting hydraulic structures in developing and developed countries.

|

|

|

These days galvanized steel wire-mesh has replaced wicker, and stones are used instead of soil, but the underlying strength of gabions is unchanged. The intrinsic flexibility of a gabion structure enables it to bend rather than break, thereby preventing loss of structural efficiency. Since gabions are bound together, they will withstand a degree of tension that would severely test a dry stone construction and be dangerous with plain concrete and masonry.

Gabion baskets can also be manufactured - literally, by hand - at village-level. This is a double advantage: it lowers the purchase cost of the baskets and creates a small rural industry, using local labour. This is in line with trends towards increasing use of labour intensive techniques in modern development projects.

|

|

Gabions are now recognised by most engineers throughout the world as being a standard construction material. FAO has long experience with gabion construction in various countries of the developing world, including Botswana, China, Egypt, Eritrea, Ethiopia, Guinea Bissau, Haiti, Niger, Malawi, Nigeria, Viet Nam, etc., where water development and irrigation projects have all made use of either imported or locally-made gabion baskets. The structures most frequently consist of earth retaining and anti-erosion structures such as retaining walls for earth excavations and embankments, sea, river and canal banks lining, small dams, spillways, weirs, groynes, etc.

|

|

The design and construction of gabion structures have not always been up to standard and, as a consequence, have caused partial or total failure of the works due to lack of (or excessive subsidence of) foundations and, most often, due to the progressive infiltration and leakage of water along the interface between the gabions and adjacent earth materials and foundations. In fact, as with any civil engineering structure, unless the same care is given and attention paid to the proper design and construction of a gabion structure the result can just as well end up in failure. However, it is worthwhile noting that the inherent flexibility and ability to survive distortion without fracture is such that a badly designed gabion structure is more likely to survive than would a similar monolithic structure.

|

|

|

The present publication is a set of practical guidelines and norms for field project engineers for the design and building of small hydraulic structures using earth and gabions. This publication would be useful in designing small earth dams with a gabion spillway, intake weirs for gravity irrigation schemes, groynes, river bed training works and for protection against hydraulic erosion.

|

|

|